Machine Vision Camera- 1-year Warranty

Enrollment Fee of $60 per item.

25% of sell price claim deductible.

Order at point of purchase.

Covers parts and labor.

Begins once manufacturer warranty

ends.

Ask us for more information!

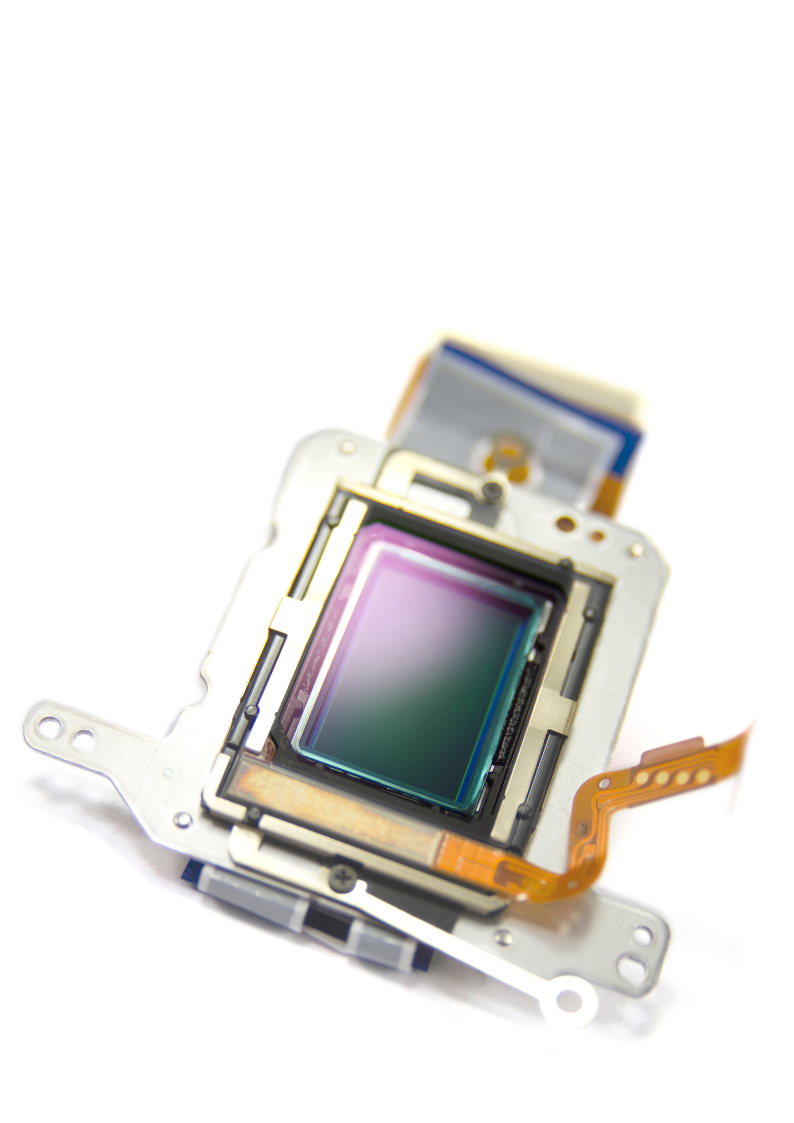

Sensor Glass Removal Labor Protection Plan

Protect your purchase! Sensor glass removal is an intensive process. While damage rates are extremely low (less than 5%) this plan protects your camera, should it be damaged during the process of sensor glass removal.

In normal circumstances, damaged cameras are not replaced or refunded. This added protection plan will insure your camera for it's sell price.

Enrollment Fee: $59.99 per camera.

Claim Deductible: 25% of the camera cost.

**Warning. Sensor glass exists to protect the sensor from damage, contamination, scratches, debris, etc. Once this cover is removed, you are exposing the sensor to possible elements. By removing the sensor glass, you acknowledge that such contamination and damage is possible. We do not offer warranty coverage or maintenance coverage for uncovered sensors after they are out in the field/in application use.

Important* Please unbox open sensor cameras in clean rooms only, with extreme care and consideration of the outside elements.

Annual Maintenance Plan

Exterior System Check/Cleaning

Decontaminate of Camera and/or Lens

with a chemical free solution

Optic/Lens safety rated solution

Internal system humidity

check/cleaning (if applicable)

Mechanical Maintenance

Ensure components performance is optimal

Validate features of camera/lens

Hardware Maintenance

Re-torque all screws to factory specs (if applicable)

Verify vibration does not affect system

Calibration Check

Recalibrate system to customer specifications (if out of spec)

Recalibrate system to factory specs

Maintenance report included with shipment

Quality Control

Full Inbound/Outbound QC of system

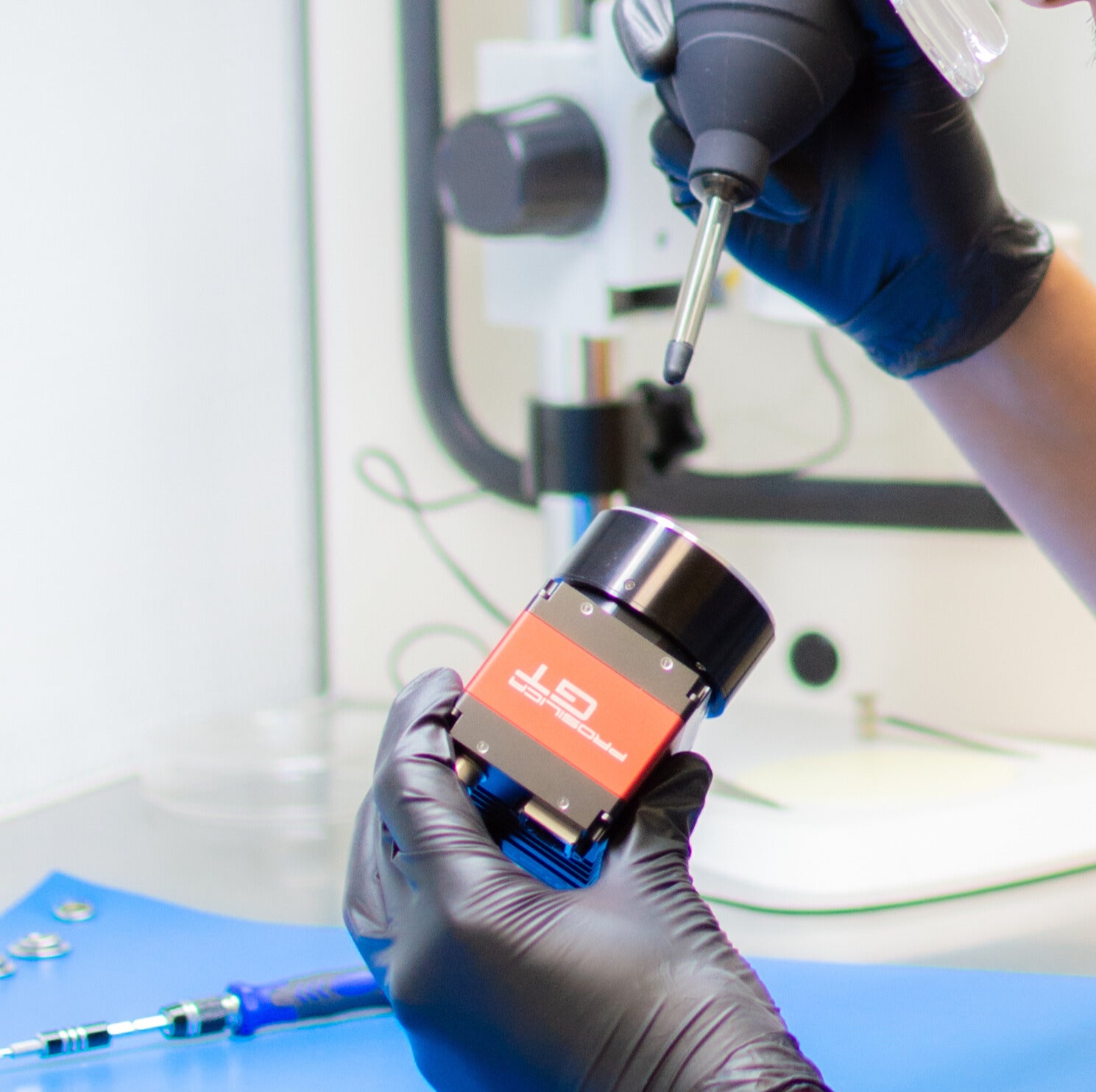

Opto-Mechanical Assemblies

With our highly trained technicians you will get the highest optical quality available. Whatever your application, robotics, auotonomous vehicles, aerospace, or manufacturing environments, we can match the correct optics to the sensor.

- Ruggedization

- Filter Installation

- Optical Testing

- Alignment

- Focusing

Opto-Electrical Assemblies

Customizing and manufacturing electrical components attached to cameras, lenses, cables, and sensors we are able to deliver a turnkey product to our clients.

- Connector Installation

- Mil-Spec

- Testing

- Custom Components

Custom Cable Build

We work on a variety of custom cabling requirements including modification, design, and build. These custom cables include but are not limited to- custom connectors, marine sealed cables, and GPIO custom length connectors.

C/CS Mount Removal

When lens mounts get in the way, we can help with that. Our technicians are highly skilled in C/CS Lens Mount removal, without compromising the structural integrity of the camera or its ability to dissipate heat from the sensor. All of our mount modifications come with a 1 year warranty.

Opto-Mechanical Ruggedization

When your application demands tight tolerances and withstanding shock and vibration you will want our certified technicians ensuring that your camera and lens assembly have no chance of coming apart. You should never have to worry that your imaging system will compromise the project due to a questionable connection. Our expert team will put your imaging system through our three part process to ensure it is ready to install right out of the box. No focusing, and no fuss.

Supply Chain Management

We can provide you with a supply chain management solution. We will handle everything from creation of the bill of materials (BOM), procurement, support, and logistics.

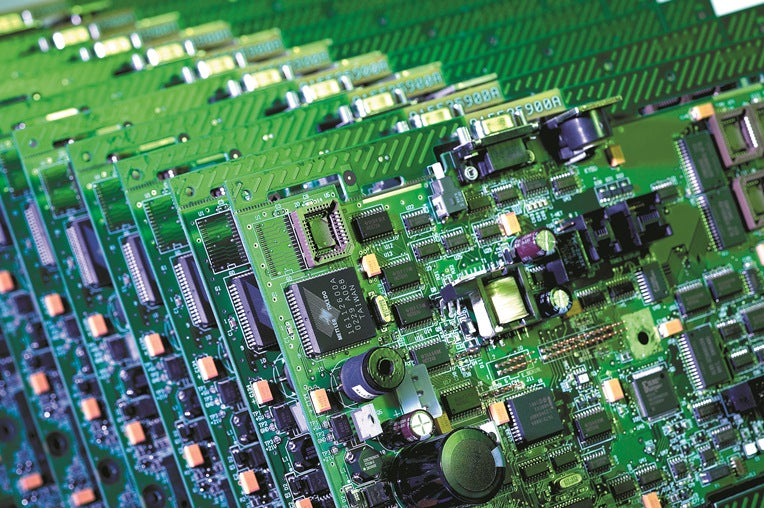

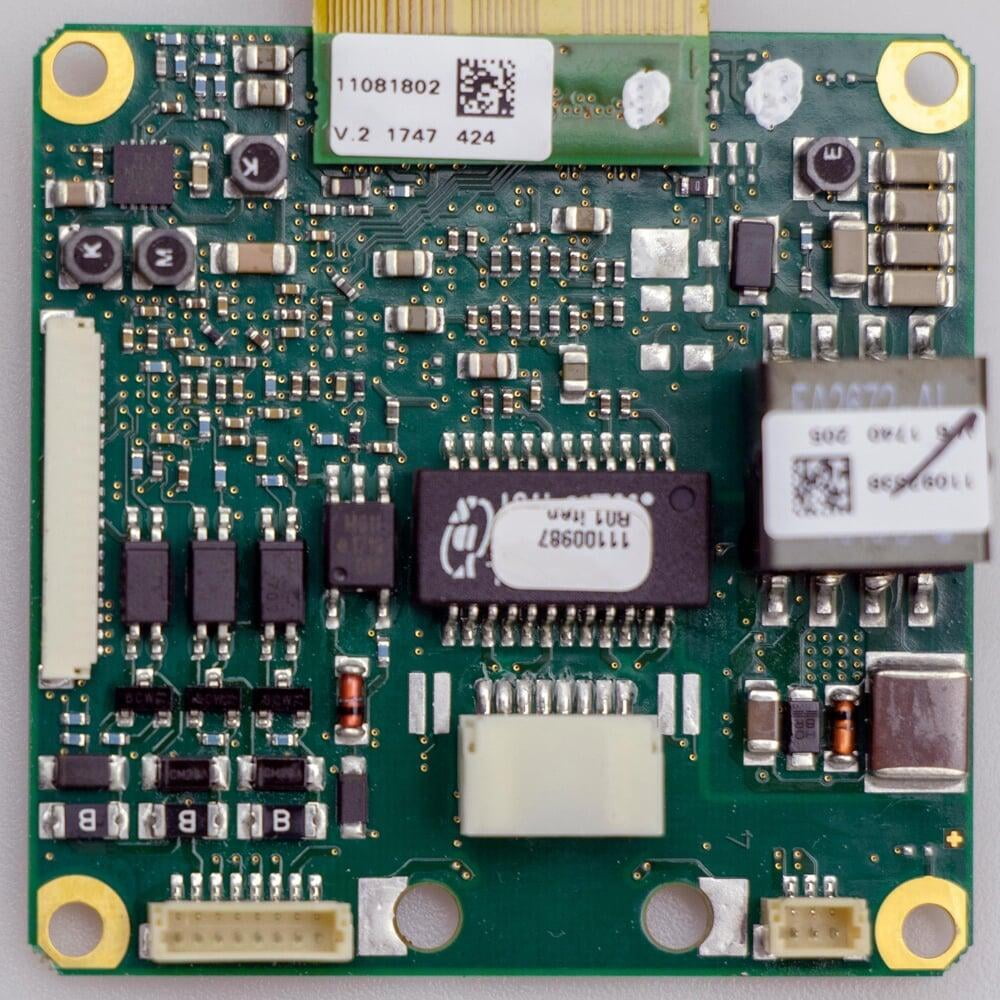

Contract Manufacturing

Wilco Imaging provides small batch manufacturing 5 to 500 unit runs of custom imaging systems and components. Our specialty is providing high-quality hand-built systems conforming to rigorous standards and demands both from customers and the environments that our systems operate. Our many years in business and continuous training have afforded our team's involvement in programs that push the limits of physics.

PCBa

Whether it is a custom board or an existing product our highly skilled technicians have many years of experience in customizing and manufacturing PCB assemblies.

- Through Hole Soldering

- Custom Layout

- Testing & Inspection

- Conformal Coatings

- Rework